Equipment Management department, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Iri bepa rinoongorora izvo zvisina kujairika zvinokonzeresa mahombe turbo expander mayuniti, inoisa mberi akatevedzana matanho ekugadzirisa matambudziko, uye kubata nzvimbo dzengozi uye matanho ekudzivirira ekushanda.Kuburikidza nekushandiswa kwehunyanzvi hwekubvisa varnish, njodzi dzinogona kuvanzwa dzinobviswa uye kuchengetedzwa kwemukati kweyuniti kunovimbiswa.

1. muchidimbu

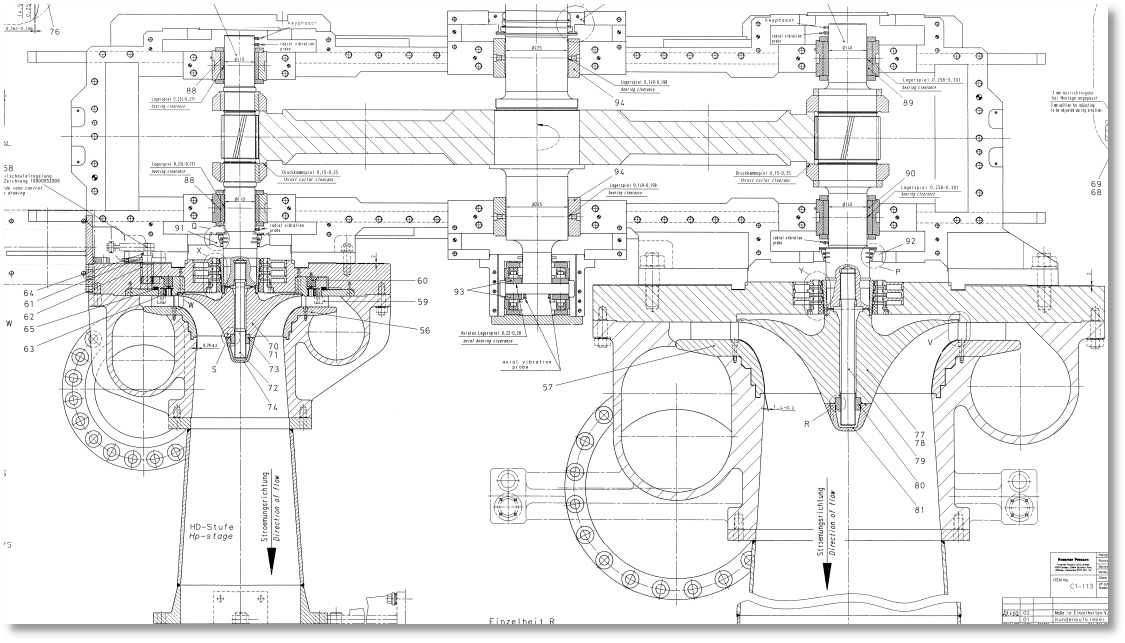

Iyo air compressor unit ye60 t/a PTA chirimwa cheYizheng Chemical Fiber Co., Ltd. ine michina kubva kuGermany MAN Turbo.Iyo unit ndeye matatu-in-one unit, umo iyo air compressor unit iri multi-shaft shanu-nhanho turbine unit, iyo condensing steam turbine inoshandiswa semuchina mukuru wekutyaira weair compressor unit, uye turbo inowedzera. inoshandiswa semhepo compressor unit.Wedzero dhiraivha muchina.Iyo turbo expander inotora yakakwirira uye yakaderera-matanho maviri ekuwedzera, imwe neimwe ine yekukweva chiteshi uye exhaust port, uye impeller inotora nzira nhatu (ona Mufananidzo 1)

Mufananidzo 1 Sectional maonero ekuwedzera unit (kuruboshwe: high pressure side; kurudyi: low pressure side)

Iwo makuru ekuita ma paramita eiyo turbo expander ndeaya anotevera:

Iyo yakakwirira-yepamusoro-yepamusoro-yekumhanya nhanho ndeye 16583 r / min, uye yakaderera-yekumanikidza parutivi kumhanya ndeye 9045 r/min;iyo yakarongerwa simba rose rekuwedzera ndeye 7990 KW, uye kuyerera kuri 12700-150450-kg/h;iyo inlet pressure ndeye 1.3Mpa, uye kupera simba ndeye 0.003Mpa.Kupisa kwekutora kwechikamu chepamusoro-soro ndeye 175 ° C, uye kupisa kwemhepo ndeye 80 ° C;kutonhora kwekutora kwechikamu chepasi-kudzvinyirira ndeye 175 ° C, uye kupisa kwemhepo kune 45 ° C;seti yemapedhi ekurerekera anoshandiswa pamativi ese ekumusoro-kudzvanya uye kuderera-kudzvanya giya shafts Bearings, imwe neimwe ine 5 pads, pombi yemafuta inopinza inogona kupinda muoiri munzira mbiri, uye fani imwe neimwe ine gomba rimwe rekupinza mafuta, kuburikidza. Mapoka matatu e15 oiri jekiseni nozzles, iyo dhayamita yeoiri inlet nozzle ndeye 1.8mm, Kune 9 maburi ekudzosa mafuta ekutakura, uye mumamiriro ezvinhu akajairwa, zviteshi zvishanu uye zvidhinha zvina zvinoshandiswa.Iyi matatu-mu-imwe unit inotora nzira yekumanikidza yekuzora yepakati pekupa mafuta kubva pachiteshi chemafuta ekuzora.

2. Matambudziko nevashandi

Muna 2018, kuti isangane nezvinodiwa zveVOC emission, nyowani yeVOC unit yakawedzerwa kune mudziyo kurapa gasi remuswe reiyo oxidation reactor, uye gasi remuswe rakabatwa rakanga richiri jekiseni mukuwedzera.Nekuti munyu webromide mugasi remuswe wepakutanga wakaiswa oxidized pakupisa kwakanyanya, kune mabromide ions.Kuitira kudzivirira mabromide ions kubva pakukora uye kupatsanura kunze kana gasi remuswe rawedzera uye kushanda mukuwedzera, zvinokonzeresa kukanganisa kwegomba kune inokudza uye inotevera michina.Nokudaro, zvakakosha kuwedzera chikwata chekuwedzera.Tembiricha yekupinda uye tembiricha yekupedza yedivi rekumanikidza uye yakaderera kudivi (ona Tafura 1).

Tafura 1 Rondedzero yekushanda tembiricha pane inopinza uye yekubuda kweiyo expander isati yasvika uye mushure mekushandura VOC

| AIHWA. | Parameter shanduko | Kushandurwa kwekare | Mushure mekushandura |

| 1 | High pressure side inotora tembiricha yemhepo | 175 °C | 190 °C |

| 2 | High pressure side exhaust tembiricha | 80 ℃ | 85 °C |

| 3 | Low pressure side inotora tembiricha yemhepo | 175 °C | 195 °C |

| 4 | Low pressure side exhaust tembiricha | 45 °C | 65 °C |

Pamberi pekushandurwa kweVOC, tembiricha yeasiri-impeller side inotakura pamucheto wakadzika wekumanikidza yakagadzikana panenge 80 ° C (iyo alarm tembiricha yekutakura pano ndeye 110 ° C, uye tembiricha yakakwirira i120 ° C).Mushure mekunge shanduko yeVOC yatangwa muna Ndira 6, 2019, tembiricha yedivi risiri-impeller inotakura pakupera kwekumanikidza kweiyo expander yakakwira zvishoma nezvishoma, uye tembiricha yepamusoro yaive padyo nepamusoro-soro yakataurwa tembiricha ye120 ° C, asi iyo tembiricha yakakwira zvishoma nezvishoma. vibration parameters haina kuchinja zvakanyanya panguva iyi (ona Mufananidzo 2).

Fig. 2 Dhiagiramu yeexpander flow rate uye isiri-drive side shaft vibration uye tembiricha

1 - kuyerera mutsara 2 - isiri-drive yekupedzisira mutsara 3 - isiri-drive shaft vibration line

3. Chikonzero chekuongorora uye nzira yekurapa

Mushure mekutarisa uye kuongorora tembiricha yekuchinja kweiyo steam turbine bearings, uye kubvisa matambudziko e-on-saiti chiridzwa chiratidziro, shanduko yemaitiro, static kufambisa kweiyo steam turbine brashi kupfeka, kumhanyisa kumhanya kwemidziyo, uye mhando yezvikamu, zvikonzero zvikuru zvekutakura kushanduka kwekushisa. vari:

3.1 Zvikonzero zvekukwira kwekushisa kweiyo isiri-impeller yedivi inotakura pane yakaderera yekumanikidza kupera kweanowedzeredza

3.1.1 Ongororo ye disassembly yakaona kuti chinhambwe chiri pakati pebearing and shaft uye meshing clearance yemazino egiya zvaive zvakajairika.Kunze kwekufungidzirwa kwevarnish pane iyo isiri-impeller side inotakura pamusoro pakadzika kudzvinyirira kupera kwekuwedzera (ona Mufananidzo 3), hapana kukanganisa kwakawanikwa mune mamwe mabheya.

Mufananidzo 3 Mufananidzo wemuviri weiyo isiri-drive yekupedzisira inotakura uye kinematic pair yeanowedzeredza.

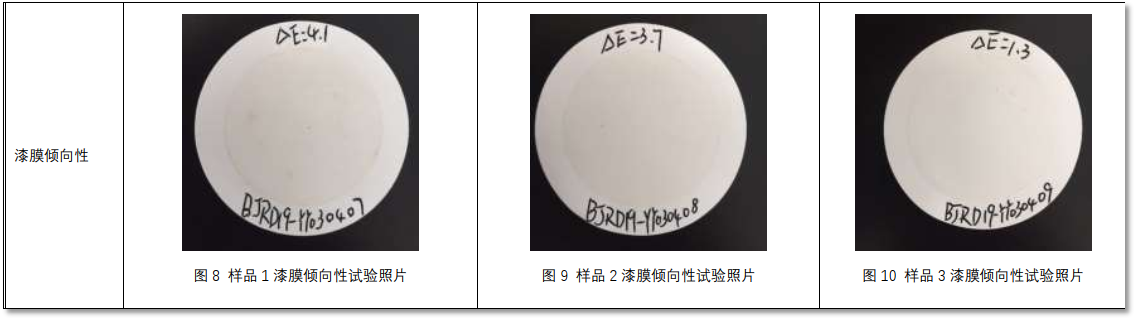

3.1.2 Sezvo mafuta ekuzora akatsiviwa kwerisingasviki gore, kunaka kwemafuta kwakapfuura bvunzo usati watyaira.Kuti ibvise kusahadzika, kambani yakatumira mafuta ekuzora kukambani yehunyanzvi kuti inoongororwa uye kuongororwa.Iyo kambani yehunyanzvi inosimbisa kuti kusungirirwa pane inotakura nzvimbo ndeyekutanga varnish, MPC (varnish propensity index) (ona Mufananidzo 4)

Mufananidzo 4 Oiri yekutarisa tekinoroji yekuongorora rondedzero yakapihwa nemafuta ekutarisa tekinoroji tekinoroji

3.1.3 Mafuta ekuzora anoshandiswa mukuwedzera ndeyeShell Turbo No. 46 turbine oil (mineral oil).Kana mafuta emaminerari ari pakupisa kwepamusoro, mafuta ekuzora ane oxidized, uye zvigadzirwa zve oxidation zvinoungana pamusoro pegwenzi rinotakura kuti riite varnish.Mineral lubricating oil inonyanya kuumbwa nezvinhu zvehydrocarbon, izvo zvakadzikama patembiricha yekamuri uye tembiricha yakaderera.Nekudaro, kana mamwe (kunyangwe nhamba diki kwazvo) yema hydrocarbon mamorekuru akasangana neoxidation reactions pakupisa kwakanyanya, mamwe ma hydrocarbon mamorekuru anozosanganawo neketani reactions, inova hunhu hwehydrocarbon chain reaction.

3.1.4 Vanamazvikokota vezvishandiso vakaita ongororo maererano nerutsigiro rwemutumbi wemidziyo, kutonhora kwepombi dzekupinza nekubuda, kuona kuvuza kweoiri, uye kuperera kwetembiricha.Uye yakatsiva seti yemabhengi kumucheto usiri wekutyaira kwepasi-kudzvanywa kwedivi rekuwedzera, asi mushure mekutyaira kwemwedzi, tembiricha ichiri kusvika 110 ℃, uyezve kwakave nekushanduka kukuru kwekudengenyeka uye tembiricha.Kugadziriswa kwakawanda kwakaitwa kuitira kuti tiswedere pedyo nemamiriro ezvinhu e-pre-retrofit, asi zvinenge pasina chero chinhu (ona Mufananidzo 5).

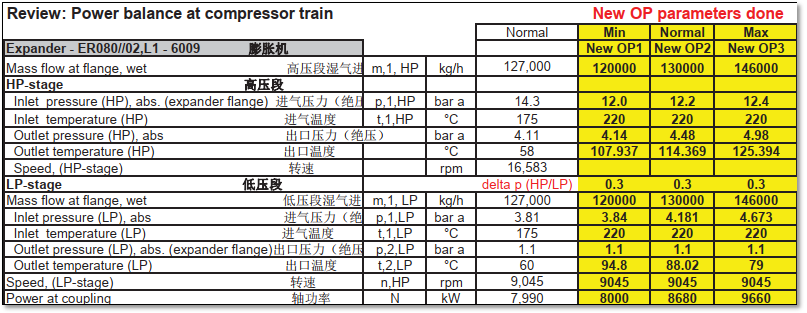

Mufananidzo 5 Trend chati yezviratidzi zvine hukama kubva Kukadzi 13 kusvika Kurume 29

iyo MAN Turbo mugadziri, pasi pemamiriro ekushanda emazuva ano ekuwedzera, kana mhepo inotora mhepo yakagadzikana pa 120 t / h, simba rekubuda ndiro 8000kw, iyo inenge iri pedyo neyokutanga kugadzirwa kwemagetsi e7990kw pasi pemamiriro ekushanda;Kana huwandu hwemhepo huri 1 30 t/h, simba rekubuda ndiro 8680kw;kana vhoriyamu yemhepo yekupinda iri 1 46 t/h, simba rekubuda i9660kw.Sezvo basa rinoitwa ne-low-pressure side account yezvikamu zviviri kubva muzvitatu zve-expander, iyo yakaderera-kudzvinyirira rutivi rwekuwedzera inogona kunge yakawandisa.Kana kutonhora kuchipfuura 110 ° C, kukosha kwekudengenyeka kunoshanduka zvakanyanya, zvichiratidza kuti varnish ichangobva kuumbwa pamusoro pemugodhi uye gwenzi rinotakura rinoputika panguva iyi (ona Mufananidzo 6).

Mufananidzo 6 Simba rekuenzanisa tafura yekuwedzera unit

3.2Mechanism Ongororo yeMatambudziko Aripo

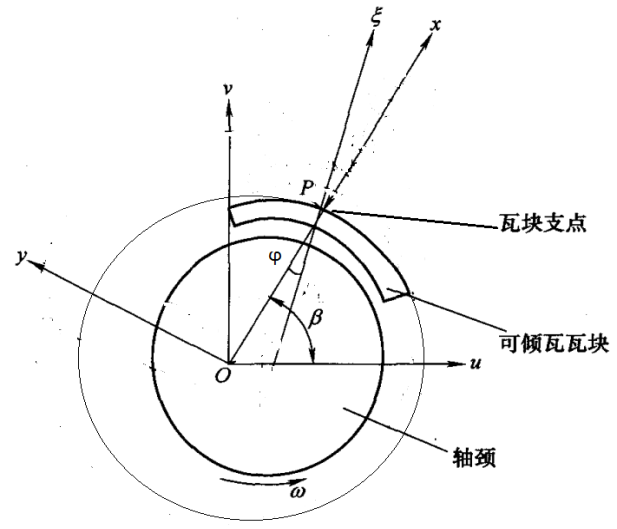

3.2.1 Sezvinoratidzwa muMufananidzo 7, zvinogona kuonekwa kuti kona yakabatanidzwa pakati pekutenderera kuduku kwekutenderera kwe fulcrum ye tile block uye mutsara wekugadzirisa mutsara muhutano hwekugadzirisa ndeye β, swing angle ye tile block is φ , uye iyo tilting pad inotakura sisitimu inoumbwa ne5 mataira, kana tirairi Kana padhi ichiiswa pasi pemafuta firimu kudzvanywa, sezvo iyo fulcrum yepadhi isiri iyo yakaomesesa muviri wakaomarara, chinzvimbo cheiyo fulcrum yepadhi mushure mekumanikidza deformation ichaita. kuburitsa kudiki kudiki padivi peiyo geometric preload kutungamira nekuda kwekuoma kweiyo fulcrum, nekudaro ichichinja kutakura clearance uye mafuta efirimu ukobvu [1.] .

Fig.7 Coordinate system ye single pad yekurerekera pad bearing

3.2.2 Inogona kuonekwa kubva kuMufananidzo 1 kuti rotor is cantilever beam structure, uye impeller ndiyo chikamu chikuru chebasa.Sezvo rutivi rwemapeller rwuri rutivi rwekutyaira, kana gasi richiwedzera kuita basa, shaft inotenderera iri padivi reimpeller iri munzvimbo yakanaka mugwenzi rinotakura nekuda kwekuita kwekuderera kwegasi, uye gaka remafuta rinoramba rakajairika.Mukuita meshing uye kuendesa torque pakati pemagiya mahombe uye madiki, neiyi senge fulcrum, iyo radial yemahara yekufamba kweiyo isiri-impeller side shaft inozoganhurwa pasi pemamiriro ekuremerwa, uye kudzvanywa kwefirimu rekuzora kwakakwira kupfuura kweimwe. mabheya, zvichiita kuti nzvimbo iyi iwedzere Kuoma kwefirimu kunowedzera, chiyero chekuvandudza firimu yemafuta chinoderera, uye kupisa kunopisa kunowedzera, zvichiita kuti varnish.

3.2.3 Varnish iri mumafuta inonyanya kubudiswa mumhando nhatu: mafuta oxidation, mafuta "micro-combustion", uye nzvimbo yepamusoro-yekushisa inobuda.Iyo varnish inofanira kukonzerwa ne "micro-combustion" yemafuta.Iyo nzira ndeyekutevera: imwe mhepo (kazhinji isingasviki 8%) ichanyungudika mumafuta ekuzora.Kana muganho wekunyungudika wadarika, mweya unopinda muoiri uchange uri mumafuta nenzira yemabhuru akamiswa.Mushure mekupinda mubereko, kudzvanywa kwepamusoro kunoita kuti mabhubhu aya apinde nekukurumidza adiabatic compression, uye tembiricha yemvura inokwira nekukurumidza kukonzeresa adiabatic "micro-combustion" yeoiri, zvichikonzera kudiki-saizi insolubles.Izvi zvisinganyungudzwi zviri polar uye zvinowanzo kunamatira kune simbi nzvimbo kuti dzigadzire varnish.Iyo yakanyanya kudzvinyirira, iyo yakaderera kunyungudika kwechinhu chisina kunyungudika, uye zviri nyore kudonha uye kugadzirisa kugadzira varnish.

3.2.4 Nekuumbwa kwevarnish, kuwanda kwefirimu yemafuta muhurumende isina kusununguka inotorwa nevarnish, uye panguva imwechete kukurumidza kwekuvandudza kwefirimu yemafuta kunoderera, uye kutonhora kunokwira zvishoma nezvishoma, izvo zvinowedzera. kupesana pakati pepamusoro pegwenzi rinotakura uye shaft, uye varnish yakaiswa inokonzera Kusapisa kwekushisa uye kukwira kwekushisa kwemafuta kunotungamirira kune yakakwirira yebhushi tembiricha.Pakupedzisira, magazini inokwesha pamusoro pevarnish, iyo inoratidzwa mukuchinja kwechisimba mu shaft vibration.

3.2.5 Kunyange zvazvo kukosha kweMPC yemafuta ekuwedzera haisi yakakwirira, kana pane varnish mumafuta ekuzora, kuparara uye kunaya kwezvimedu zvevarnish mumafuta kunogumira nekuda kwekusakwanisa kwemafuta ekuzora kunyungudika. mavara evarnish.Iine dynamic balance system.Kana ichinge yasvika panzvimbo yakaguta, iyo varnish inorembera pabearing kana kutakura padhi, zvichikonzera kushanduka kwekushisa kwebearing pad, iyo injodzi huru yakavanzika inokanganisa kushanda kwakachengeteka.Asi nekuti inonamatira kune inotakura padhi, ndicho chimwe chezvikonzero zvekukwira kwekushisa kwebearing pad.

4 Zviyero uye Zviyero

Kubvisa kuunganidzwa kwevarnish pakutakura kunogona kuve nechokwadi kuti kutakura kweyuniti kunomhanya pane inodzorwa tembiricha.Kuburikidza nekutsvagisa nekutaurirana nevazhinji vagadziri vevarnish yekubvisa midziyo, takasarudza Kunshan Winsonda, ine yakanaka yekushandisa mhedzisiro uye mukurumbira wemusika, kugadzira WVD-II electrostatic adsorption + resin adsorption, inova musanganiswa varnish yekubvisa midziyo yekubvisa pendi.membrane.

WVD-II akatevedzana oiri anonatsa anonyatso batanidza electrostatic adsorption yekuchenesa tekinoroji uye ion yekutsinhana tekinoroji, kugadzirisa yakanyungudika varnish kuburikidza neresin adsorption, uye kugadzirisa iyo yakanaya varnish kuburikidza ne electrostatic adsorption.Iyi tekinoroji inogona kuderedza zvirimo zvesludge munguva pfupi , Munguva pfupi yemazuva akati wandei, iyo yepakutanga lubrication system ine yakawanda sludge / varnish inogona kudzoserwa kune yakanakisa yekushanda mamiriro, uye dambudziko rekunonoka kukwira mukati. tembiricha yekusimudza inotakura inokonzerwa nevarnish inogona kugadziriswa.Inogona kunyatso kubvisa uye kudzivirira iyo inonyungudika uye isina-inonyungudika mafuta sludge inogadzirwa panguva yenguva dzose kushanda kweiyo steam turbine.

Nheyo dzayo huru ndeidzi:

4.1 Ion kuchinjanisa resin kubvisa varnish yakanyungudika

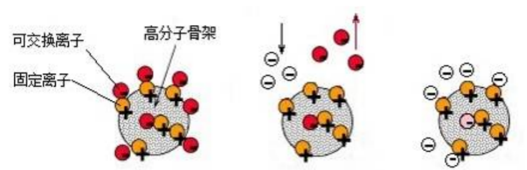

Ion exchange resin inonyanya kuumbwa nezvikamu zviviri: polymer skeleton uye ion exchange group.Iyo adsorption musimboti inoratidzwa muMufananidzo 8,

Mufananidzo 8 Nheyo yeion-interaction resin adsorption

Boka rekuchinjana rakakamurwa kuita chikamu chakagadziriswa uye chikamu chinofambiswa.Chikamu chakagadziriswa chinosungirirwa pane polymer matrix uye haigoni kufamba zvakasununguka, uye inova ion yakagadziriswa;chikamu chinofambiswa uye chikamu chakamisikidzwa chinosanganiswa neiyo ionic zvisungo kuti ive iyo inochinjana.Ioni dzakagadziriswa uye ma ions enhare ane mhosva dzakapesana zvakateerana.Pagwenzi rinotakura, chikamu chinofamba chinoparara kuva ions yakasununguka inofamba, iyo inotsinhanisa nezvimwe zvinosvibisa zvigadzirwa zvine mutero wakafanana, kuitira kuti zvibatanidze neiyo yakagadziriswa ions uye zvakasimba adsorbed pachigadziko chekuchinjana.Paboka, inotorwa nemafuta, yakanyungudutswa varnish yakabviswa neion exchange resin adsorption.

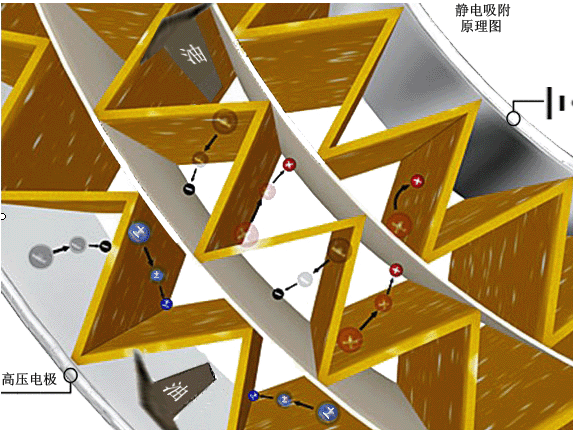

4.2 Electrostatic adsorption tekinoroji yekubvisa yakamiswa varnish

Electrostatic adsorption tekinoroji inonyanya kushandisa yakakwira-voltage jenareta kugadzira yakakwira-voltage electrostatic munda kuparadzanisa zvidimbu zvakasvibiswa muoiri kuratidza zvakanaka uye zvakaipa kuchaja zvichiteerana.Zvikamu zvisina kwazvakarerekera zvinosvinwa uye zvinofambiswa nezvikamu zvinopomerwa, uye pakupedzisira zvimedu zvose zvakashambadzirwa uye zvakabatanidzwa kune muunganidzi (ona Mufananidzo 9).

Mufananidzo 8 Nheyo ye electrostatic adsorption tekinoroji

Electrostatic oiri yekuchenesa tekinoroji inogona kubvisa zvese zvisinganyunguriki zvinosvibisa, kusanganisira kusviba uye yakamiswa varnish inogadzirwa nekuora kweoiri.Nekudaro, zvechinyakare mafirita zvinhu zvinongobvisa zvimedu zvakakura zvine hutsanana hunoenderana, uye zvinonetsa kubvisa submicron. level yakamiswa varnish .

Iyi sisitimu inogona kugadzirisa zvachose varnish inonaya uye yakaiswa pane inotakura padhi, nekudaro ichigadzirisa zvachose pesvedzero yebearing pad tembiricha uye vibration shanduko inokonzerwa nevarnish, kuitira kuti iyo unit inogona kumhanya yakadzikama kwenguva yakareba.

5 Mhedziso

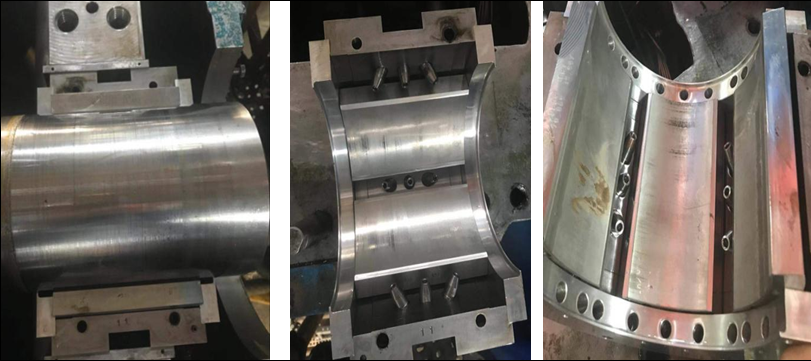

WSD WVD-II varnish yekubvisa unit yakaiswa mukushandiswa, kuburikidza nemakore maviri ekutarisa oparesheni, tembiricha yekutakura yakagara ichichengetedzwa kunosvika 90 ° C, uye iyo unit yakaramba ichishanda yakajairika.Imwe firimu yevarnish yakawanikwa (ona Mufananidzo 10).

Mufananidzo wemuviri wekubereka disassembly mushure mekuisa varnish kubviswa

midziyo

mareferensi:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, uye Chen Zhujie.Nhamba yekuenzanisa uye yekuyedza kutsvagisa pane anochinja maitiro epivot elastic uye kunyorovesa tilting pad bearings [J].Chinese Journal of Mechanical Engineering, Gumiguru 2014, 50(19):88.

Nguva yekutumira: Zvita-13-2022