Munguva yekugadzira maitiro e petrochemical Enterprises,

Iwatewater discharge volume yakakura uye kuumbwa kwakaoma.

Iyo yekubatanidza maitiro yakaoma kubata nayo!

Kunyanya iyo yakakwira-munyu uye yakakwira-COD mai doro kumagumo,

Kana isingakwanisi kuomeswa zvakanaka,

Ichakanganisa zvakanyanya kuitika kwe "zero discharge" yetsvina yemvura!

Yakajairika maitiro ekuomeswa kwaamai doro pakupera kwe petrochemical wastewater treatment process

Mukugadzira mabhizinesi epetrochemical, iyo evaporation / kutonhora crystallization maitiro inowanzoshandiswa maitiro ekuita kuti uwane chigadzirwa chekupedzisira.Iyo crystallization process inotungamira mukupfumiswa kwehutsvina mune izvo zvinhu, saka yakawanda kana kushoma evaporated amai doro richagadzirwa mukugadzira maitiro.

Parizvino, kurapwa kweaya mai evaporated zvinwiwa zvinogadziriswa sedambudziko chairo mukugadzira.Pamusana pezvinhu zvakasiyana-siyana zvedoro raamai pacharo, nzira dzekurapa dzinosiyanawo.Pakurasa doro raamai rakaputika rine munyu wakakwira uye COD yakakwira, matekinoroji ekurapa ari pamusika anonyanya kuomesa chigubhu, kuomeswa kwerake, keturu imwechete uye tembiricha yakaderera evaporation crystallization process.Hunhu hwematanho mana makuru maererano nekugadzirisa kugona, kushandiswa kweutsi, mashandisiro emagetsi, mashandiro eparameta, hunhu hwemidziyo uye chiyero chekushandisa zvinofananidzwa sezvizvi:

| Equipment type | kukwanisa | kushandiswa kwemhepo | Simba rekushandisa | Operating parameters | Equipment Features | Range yekushandiswa |

| Roller scraper drying | 5000L/d | 1.5t/tani mvura | 22W | Vacuum drying, kuomesa mumhepo Pamusoro pe60 ℃ | Chimiro chakareruka, kushanda kuri nyore, nheyo iri nyore | High concentration yaamai doro, high C00 substance |

| Kuiswa chisimbiso kwemidziyo hakuna kunaka, kunhuhwirira kwepa-saiti kwakakura, uye kuchengetedzwa kwevashandi kwakashata. | ||||||

| Inogona kupiswa nemafuta ekutamisa kupisa, steam, nezvimwe. | ||||||

| Simbi isina tsvina, duplex simbi zvinhu | ||||||

| Target kuomesa | 5000L/d | 1.5t/tani mvura | 22W | Vacuum drying, kuomesa mumhepo Pamusoro pe60 ℃ | Chimiro chacho chiri nyore, kushanda kuri nyore, nzvimbo yepasi yakakura, chiyero chekugadzirisa chemidziyo yakaderera, uye tembiricha yekushandisa yakakwira. | High concentration yaamai doro, high C00 substance |

| Inogona kupiswa nemafuta ekutamisa kupisa, chiutsi, mvura inopisa, nezvimwe. | ||||||

| Simbi isina tsvina, duplex simbi zvinhu | ||||||

| Single Still | 5000L/d | 1.2t/tani mvura | 25W | Vacuum distillation, atmospheric distillation Pamusoro pe60 ℃ | Inoda kugadzira chikuva, asi musimboti wemidziyo iri nyore uye kushanda kuri nyore.Pfuurira kune iyo inoratidzika sevhisiki zvinhu, kuburitsa kwakawedzera hemp | High concentration yaamai doro, high C00 substance |

| Inogona kupiswa nemafuta ekutamisa kupisa, steam, nezvimwe. | ||||||

| Enamel zvinhu | ||||||

| Low tembiricha steam crystallization | 5000L/d | 1.1t/tani mvura | 7.5W | yakaderera tembiricha evaporator 30-400 | Yakakwira dhigirii rekubatanidza, yakakwira degree re otomatiki, kuiswa chisimbiso kwakanaka kwemidziyo, hapana kunhuhwirira kwakasarudzika mukushanda kwe-saiti, tembiricha yekushanda yakaderera, hapana kudiwa kwevashandisi vakasarudzika panzvimbo. | Yakanyanya kunyura mai doro, yakakwira COD zvinhu, kupisa kusinganzwisisike zvinhu |

| Stainless simbi, duplex simbi, titanium, nezvimwe. |

△Kuenzanisa kuongororwa kweyakajairwa kuomesa midziyo uye yakaderera tembiricha steam crystallization process

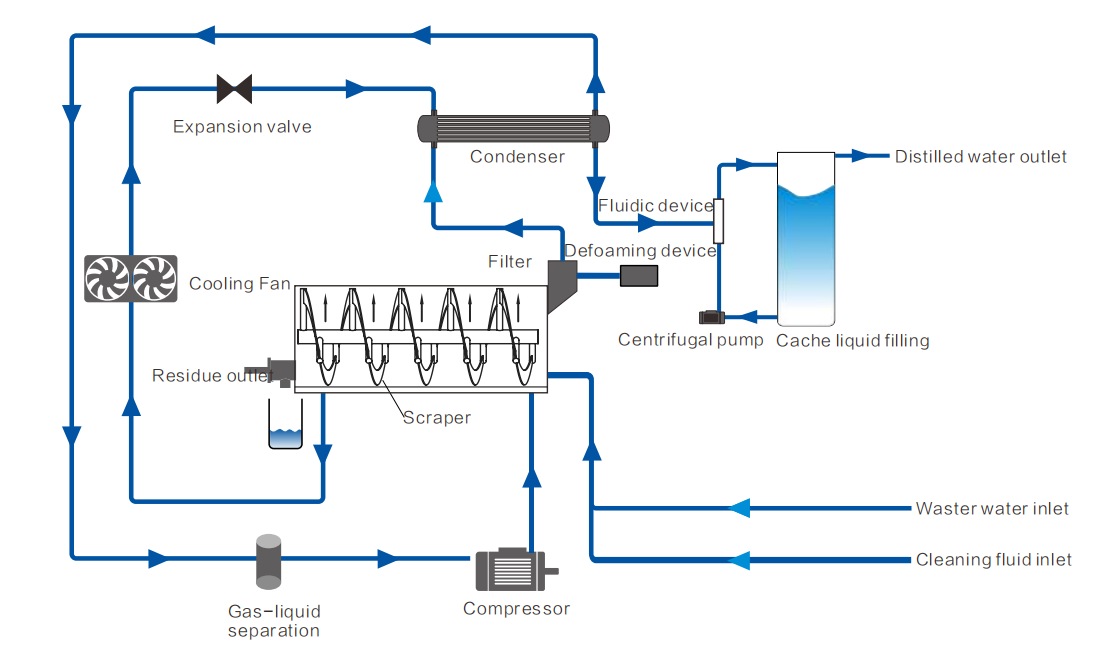

Weishengda kuchengetedzwa kwezvakatipoteredza yakaderera-tembiricha evaporation crystallizer inonyanya kushandiswa kudzikisa uye kusungirirwa kwepamusoro-yakadzika tsvina.Iyo yakavakirwa-mukati scraper inoshanda zvakanyanya mukurapa yakadzika mvura iyo iri nyore kunamatira kumadziro.Inonyanya kukurudzirwa kurapwa kwekubatana kana crystallized zvinwiwa, senge heavy metal wastewater, high brine, mai doro, reverse osmosis concentrated mvura, etc. Iyo system inotora Miller plate bhachi rekuchinjana kupisa, iyo vacuum dhigirii mukamuri yekubuda -95~-97kPa, uye tembiricha yekubuda kwemhepo inowanzochengetedzwa pakati pe40~45°C.Iyo evaporation chamber inoshandisa spiral scraper kubvongodza, iyo inogona kuvimbisa kupisa kwakafanana.Panguva imwecheteyo, kuseta shaft inosimudzira kupisa kunogona kuwedzera kupisa kwekuchinjana uye kunatsiridza kuoma kwekubuda.

Iyo sisitimu inokwana otomatiki kudzora, iine hunhu hwekuburitsa otomatiki, otomatiki kuchenesa, zvishandiso Cloud platform management uye zvichingodaro.Mhedzisiro yekubuda kwemvura yakanaka, hapana kusvibiswa kwegasi, kusvibiswa kwekupisa uye zvimwe zviitiko, uye hurongwa hwese hunoshanda nenzira yakavharwa.

△ Kushanda musimboti dhizaini yeyakadzika tembiricha evaporation crystallizer

2 Yakajairika kushandiswa kweWSD yakaderera-tembiricha evaporation crystallization process mune petrochemical wastewater

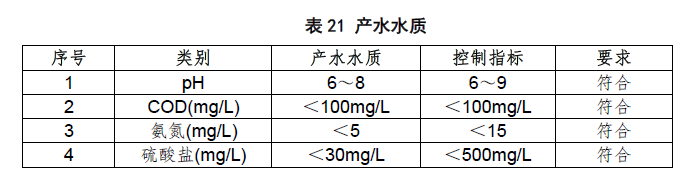

Mutengi ibhizimusi remafuta uye gasi rinonyanya kugadzira gasi rechisikigo.Huwandu hukuru hwemvura yakasviba isina kurerekera, yakajairwa yakadzoserwa mvura, inotenderera yemvura tsvina uye bhoiler effluent inogadzirwa.Pane dambudziko remvura ine munyu yakawanda, iyo ine simba guru pamudziyo wekuchenesa tsvina.Iyo yakanyanya-munyu tsvina ine sodium sulfate uye yakakwirira COD kukosha.Mushure meWSD skid-yakaiswa amai doro drying system (zuva nezuva kurapwa mvura yetsvina 10m³), mvura inogadzirwa haina ruvara uye haina kunhuhwirira kunopinza, uye pH kukosha iri pakati pe6 ne9. L, uye COD iri pasi pe40mg / L, mvura inogadzirwa inokodzera, iyo inosangana nezvinodiwa zvekupinda mudziva rebiochemical kurapwa uye inosanganawo nezvinodiwa zvemvura.

△ Pa-saiti kesi mepu

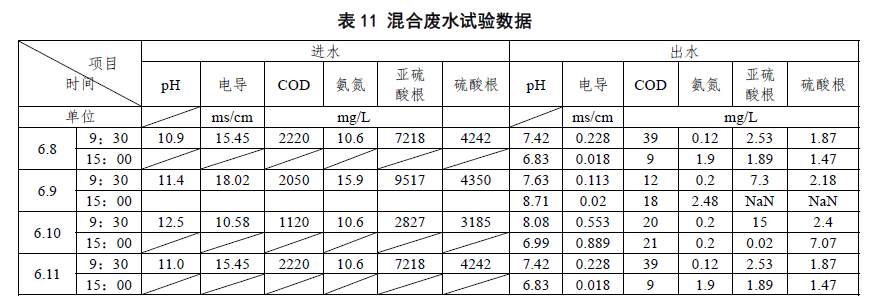

△Edza data uye tafura yemhando yemvura

△Mapikicha emvura inogadzirwa uye slag discharge

Zero discharge treatment ye petrochemical wastewater ndiyo ramangwana rekusimudzira gwara.Kudzikiswa kwakanyanya kwepetrochemical tsvina yemvura neinodzika-tembiricha evaporation tekinoroji inogona kunyatso kudzikisa kuremerwa kwekubuda kwemhepo uye crystallization, kuderedza mutengo wakakwana weinjiniya yekurapa zero-discharge, uye kupa referensi uye referensi yekushandisa uye kusimudzira zero-discharge tekinoroji. petrochemical indasitiri mune ramangwana.

Nguva yekutumira: Jul-11-2023